structured packing

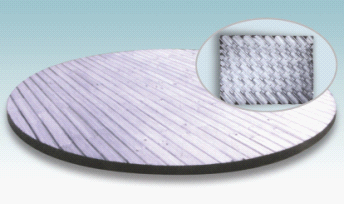

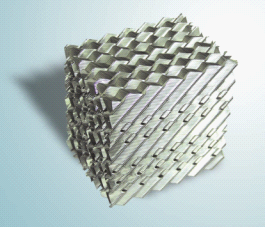

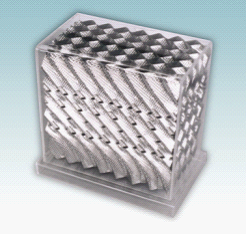

Sheets Combined Corrugated Structured Packing (Zupak)

Each periodic ripple of the Zupak is composed of more than four intermittent planar graphic sheets located on four planes. The lateral projection shape is two interlaced corrugated lines. The uniform parallelogram channel on the filler has completely replaced the circular holes on the regular structured packing. It can not only save 8.5% of the material, but also increase the specific surface area of the corresponding quantity. The packing has the advantages of low pressure, large flux, good transversal air permeability and high separation ability. It can be widely used in the industrial fields of distillation, absorption, extraction, heat exchange, washing and so on.

Compared to corresponding Mellapak Structured Packing,

Zupak has Structured Packing advantages as follows:

The Structured Packing specific area increases by around 10%;

The Structured Packing porosity opening rate increases by 30-40%;

The Structured Packing separation efficiency increases by about 10%;

The Structured Packing throughout increases 20%;

The Structured Packing pressure drop decreases around 30%.

The specifications of Zupak Structured packing are as follows:

| Model | Nominal Specific Area, m2/m3 | Peak height, mm | Peak distance, mm | Inclination Angle of Corrugation, o |

|

| Basic Dimension | Allowable Tolerance | Basic Dimension | Allowable Tolerance | Basic Dimension | Allowable Tolerance |

| 100X | 100 | 31.8 | ±0.5 | 51.5 | ±1.0 | 30 | ±2 |

| 100Y |

|

|

|

|

| 45 |

|

| 125X | 125 | 23.8 | ±0.5 | 44 | ±1.0 | 30 | ±2 |

| 125Y |

|

|

|

|

| 45 |

|

| 150X | 150 | 21 | ±0.5 | 34.3 | ±1.0 | 30 | ±2 |

| 150Y |

|

|

|

|

| 45 |

|

| 200X | 200 | 15.8 | ±0.5 | 25.7 | ±1.0 | 30 | ±2 |

| 200Y |

|

|

|

|

| 45 |

|

| 250X | 250 | 11.9 | ±0.5 | 23.8 | ±0.5 | 30 | ±2 |

| 250Y |

|

|

|

|

| 45 |

|

| 350X | 350 | 8.6 | ±0.5 | 16.2 | ±0.5 | 30 | ±2 |

| 350Y |

|

|

|

|

| 45 |

|

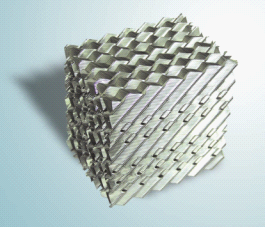

Peak Valley Corrugated Structured Packing (Dapak)

On the wave peak of each cycle of the packing, the rule is discontinuous to open the valley section of the triangle in the shape of the section. The two valley surfaces that constitute the valley are trapezoid or parallel quadrilateral. The depth of the valley is less than the height of the 1/2 wave peak. In the wave valley of each periodic ripple of the packing, the section of the section with triangular shape is opened intermittently. The two peaks of the peak section are the trapezium or parallel quadrilateral in the upper and lower parts. The height of the peak is less than the 1/2 trough depth. The packing has small pressure drop, large flux, good transversal air permeability and high separation capacity. And it is easy to make, the stiffness and strength of the packing piece are not affected, and there is no "mutual bite" phenomenon between the fillers and can be installed.

Compared to commonplace Structured packing, Dapak Structured packing has advantages like:

The separation efficiency increases by 10%;

The flux rise by 20%;

The pressure drop decreases 30%

From its inception in 1997, Dapak structured packing has been successively applied in refinery, petrochemical, fine chemical, food, medicine, environment protection and other industry.

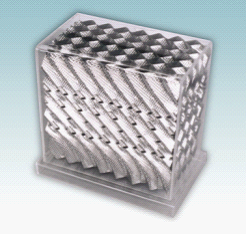

Bidirectional Curvelet Structured Packing ( Chaopak)

The structure features of Chaopak Packing include bidirectional curvelet, curved channel, oblique stagger arrangement, rotation by 90o for installation.

Compared to corresponding unidirectional ramp packing, it is characterized by higher flux and lower pressure drop.

Research shows that the flux of CHAOPAK - 250Y is higher than that of ordinary 250Y, and the flux is increased by 25~50% and the pressure drop is reduced by 30~60%. It has been successfully used in many large pagodas

Referenced Products by SL Tec

Address: No.10 Bldg 31 Second St., Charbagh St. Punak Sq., Tehran, Iran

Sales Representative: Mr. Mohammad Hassan Shabani

Tel: +98 912 179 8879

E-mail: sales01@slchemtech.com

None

None

None