Fixed Bed Process Hydrogen Peroxide

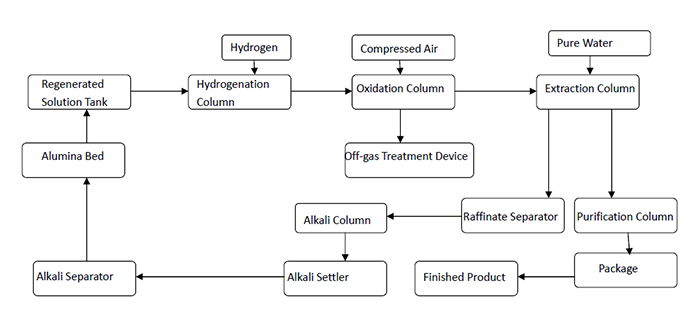

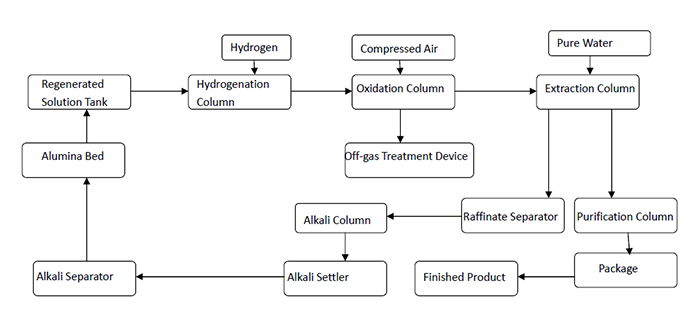

There are several methods for hydrogen peroxide production and manufacturing, among them the

AO(auto-oxidation) process is the most prevailing one. In this process, 2-alkyl

anthraquinone is mixed with organic solvent to make up the working solution,

which is hydrogenated in presence of catalyst, and the resulting is oxidized by

air (or oxygen) in counter-current way before being extracted, regenrated,

purified and enriched to get commercial hydrogen peroxideproduct. Depending upon

the different reactor type in the hydrogenation unit, AO process is further

divided into Fixed Bed Reactor Process and Fluidized Bed Reactor Process.

Introduction of Anthraquinone Method

At present, the industrial production of hydrogen peroxide in the world basically uses anthraquinone method (this method was started by DuPont Company in 1953), which takes alkyl anthraquinone as the working carrier.

In China, 2-ethyl anthraquinone(EAQ)is mainly used as the working carrier. Dissolve EAQ in organic solvents(generally composed of heavy aromatics and trioctyl phosphate (TOP) in certain proportion) to form working fluids, hydrogenation and oxidation are then carried out under the action of catalyst (palladium catalyst) to produce hydrogen peroxide (H2O2) and H2O2 is extracted from the working fluid with pure water to obtain hydrogen peroxide with H2O2 content of 27.5%, which is concentrated and reprocessed into other specifications.

SL Tec is a leading supplier of technology and turnkey solutions and services for hydrogen peroxide manufacturing and hydrogen peroxide production plants. SL Tec provides both fixed bed reactor process and fluidized bed reactor process. The fixed bed reactor process SL TEC provides is the

most advanced technology in China. It employs heavy aromatics-TBU-TOP tertiary

solvent in the working solution and alumina-supported Pd catalyst with high

activity. Learn more

Welcome to contact us to get professional guidance for hydrogen peroxide production cost for gydrogen peroxide plant.

You May Also Like

●How Is Hydrogen Peroxide Made?

●New Process Can Deliver Hydrogen Peroxide In Remote Areas

●Hydrogen Peroxide Can Be Used As a Sterilant

●Is Hydrogen Peroxide Useful For Treating Water Pollution?

●Hydrogen Peroxide Plant Supplier Shares Knowledge About Hydrogen Peroxide

Features of Fixed Bed Process Hydrogen Peroxide

The fixed bed hydrogenation reactor setup for hydrogen peroxide production, specifically the technology offered by SL TEC, boasts several advantages over other fixed bed reactor processes prevalent in China. Here are the key features of this hydrogen peroxide process:

Advanced Control and Safety Systems

The fixed hydrogen peroxide system incorporates an advanced Distributed Control System (DCS), a Safety Instrumented System (SIS), and an industrial video monitoring system.

This setup ensures optimal control, alarms, and safety interlocks for various process parameters during the hydrogen peroxide production process, resulting in a stable, high-yield, low-cost, and safe operation.

Efficient Distillation Technology

The concentration of hydrogen peroxide utilizes cutting-edge hydrogen peroxide distillation technology through falling film distillation.

This method minimizes the residence time of the hydrogen peroxide solution in the evaporator, preventing decomposition of the product.

Additionally, low-pressure saturated steam is employed to maintain an effective temperature difference of 8 to 10 °C, which conserves steam consumption and reduces unit costs.

Effective Wastewater Treatment

Centralized Emission Management

The system features a centralized air release mechanism for recovering and disposing of unorganized exhaust gases.

This innovation eliminates onsite odors, reduces solvent consumption, enhances the working environment, and meets occupational health and environmental protection standards.

Enhanced Drying Column Design

The post-treatment drying column employs high-efficiency reaction and separation filler packing.

This design resolves issues related to alkali formation in the drying column and alleviates the burden on subsequent activated alumina beds, thereby reducing their consumption while ensuring long-term operational stability.

High-Efficiency Purification

A purification column utilizing high-efficiency oil-water separation coalescing fillers significantly lowers organic carbon content in the final product.

This ensures that the organic carbon levels meet high-end user requirements without necessitating further purification.

Tail Gas Recovery Process

The treatment of tail gas employs a high-efficiency solvent recovery process that combines turbo expansion refrigeration with carbon fiber adsorption recovery.

This innovative approach allows for the recovery of up to 80% of solvents from low-temperature exhaust gases, thereby extending the lifespan of activated carbon fibers and minimizing regeneration frequency.

Optimized Extraction Technology

The high-efficiency extraction column ensures optimal oil-water separation and extraction technology, achieving high extraction concentrations with minimal raffinate waste.

The design allows for stable production of hydrogen peroxide with concentrations exceeding 35%, while reducing extraction column volume by 20% compared to conventional processes.

Advanced Oxidation Column Design

Utilizing a gas-liquid mixed high-efficiency oxidation column enhances the thorough mixing of oxidizing working fluids with air oxygen.

This design has been successfully applied in multiple equipment setups, achieving an oxidation collection rate exceeding 98%.

Cost Efficiency

The overall production costs are nearly halved compared to traditional methods.

The SL TEC oxidation system employs advanced operational techniques to lower oxidation operating pressures while maintaining yield efficiency.

For instance, the outlet pressure for air compressors has been reduced from 0.5–0.6 MPa to 0.40–0.45 MPa, yielding a 20% energy saving.

Superior Catalytic Performance

The palladium catalyst used in the hydrogenation reaction exhibits high catalytic activity and exceptional selectivity for cesium hydrogenation.

This results in reduced enthalpy consumption—less than 0.2 kg per ton of product (27.5% concentration)—which is one-fifth of the industry average, leading to significant reductions in overall chemical raw material consumption.

These features collectively position SL TEC's fixed bed hydrogenation reactor setup as a leading technology in the efficient production of hydrogen peroxide, emphasizing sustainability and cost-effectiveness while maintaining high safety standards.

Transform your production process and reduce costs significantly! Get in touch with SL Tec today and learn how our advanced solutions can benefit your business!

None

Specification of Fixed Bed Process Hydrogen Peroxide

| Item | Index |

| 27.5% | 35% | 50% | 60% | 70% |

| Superior Grade | Acceptable Grade |

| Hydrogen Peroxide Mass Fraction(%) | 27.5 | 27.5 | 35.0 | 50.0 | 60.0 | 70 |

| Free Acid (as H2SO4) Mass Fraction(%) | 0.040 | 0.050 | 0.040 | 0.040 | 0.040 | 0.040 |

| Non-volatile Mass Fraction (%) | 0.08 | 0.10 | 0.08 | 0.08 | 0.06 | 0.06 |

| Stability(%) | 97.0 | 90.0 | 97.0 | 97.0 | 97.0 | 97.0 |

| Total Carbon (in C) Mass Fraction (%) | 0.030 | 0.040 | 0.025 | 0.035 | 0.045 | 0.050 |

| Nitrate (in terms of NO3) Mass Fraction (%) | 0.020 | 0.020 | 0.020 | 0.025 | 0.028 | 0.035 |

| Note: Total carbon and nitrate are non-mandatory requirements, and other items are mandatory. |

|

The hydrogen peroxide content indicator is the guaranteed value at the time of shipment. Under the conditions of storage and transportation under standard conditions, the reduction rate of hydrogen peroxide content within six months is:

| Superior Grade | First Grade | Acceptable Grade |

| 4% | 5% | 8% |

Operational Indicator Guarantee

| S/N | Item | Indicator Guaranteed Value (by 100% load) |

| 10000t/a(27.5%) |

| 1 | Working Fluid Flow | 50m3/h |

| 2 | Hydrogenation Efficiency | ≥8.0g/L |

| 3 | Oxidation Yield | ≥95% |

| 4 | Hydrogen Peroxide Content in Raffinate | ≤0.1g/L (when the product is 27.5% concentrated) |

| ≤0.15g/L(when the product is 30% concentrated) |

| ≤0.20g/L(when the product is 35% concentrated) |

| 5 | Product Concentration | The concentration is adjustable from 27.5% to 50% |

Note: The device operation flexibility is 60~110%.

Specific Consumption of Fixed Bed Process Hydrogen Peroxide

(1 Specific Consumption based on per ton of 27.5% hydrogen peroxide

| S/N | Item | Unit | Unit Consumption Guarantee Index | Expectation Index |

| 1 | H2 | Nm3 | 200 | 200 |

| 2 | 2-ethyl hydrazine | kg | 0.2 | 0.1 |

| 3 | Trioctyl Phosphate | kg | 0.1 | 0.8 |

| 4 | Heavy Aromatic Hydrocarbon | kg | 2 | 1.5 |

| 5 | Phosphate | kg | 0.6 | 0.5 |

| 6 | Potassium Carbonate | kg | 0.5 | 0.5 |

| 7 | Activated Alumina | kg | 3 | 2.5 |

| 8 | Catalyst | kg | 0.067 | 0.05 |

| 9 | Steam | t | 0.6 | 0.05 |

| 10 | Demineralized Water | t | 0.8 | 0.8 |

| 11 | Power (including main equipment, air pressure, circulating water, nitrogen production) | kwh | 180 | 170 |

(2 Specific Consumption based on per ton of 50% hydrogen peroxide

| S/N | Item | Unit | Guarantee Index |

| 1 | 27.5% concentration | t | 1.85 |

| 2 | Steam | t | 0.8 |

| 3 | Cooling Water | t | 80 |

| 4 | Demineralized Water | t | 0.6 |

| 5 | Power Supply | kWh | 15 |

Main Raw Material Consumption Guarantee of Fixed Bed Process Hydrogen Peroxide

| S/N | Item | Unit | Index | Explain |

| 1 | Palladium Catalyst | t | 4 | Service Life ≥ 5 years |

| 2 | Activated Alumina | t | 24 | Original Driving Load |

| 3 | System Working Fluid | m3 | 100 | Total System Working Fluid |