ACR is a copolymer of monomers such as methyl methacrylate and acrylate. ACR is the best impact modifier developed in recent years. It can increase the impact strength of materials dozens of times. ACR is an impact modifier with a core-shell structure. The shell is composed of methyl methacrylate-ethyl acrylate polymer, and the segments with rubber elastomer cross-linked by butyl acrylate as the core are distributed in the inner layer of the particles. It is especially suitable for impact modification of PVC plastic products for outdoor use. The use of ACR as an impact modifier in PVC plastic door and window profiles has good processing performance, smooth surface, good aging resistance, and high welding fillet strength compared with other modifiers. Features, but the price is about 1/3 higher than CPE. Commonly used brands abroad such as K-355, generally use 6-10 parts.

ACR is mainly used to improve the impact properties and processability of PVC. PVC is important among general plastics. It has high strength, low price and flame retardancy. However, its poor impact resistance limits its application in the field of building materials. Among the impact modifiers of PVC, ACR can greatly improve the impact resistance of PVC, while maintaining its strength, and can significantly improve the melt fluidity, thermal deformation, weather resistance and surface gloss of PVC products.

ACR impact resistant modifier has also been widely used in engineering plastics such as polymethylmethacrylate (PMMA), polycarbonate (PC), polyester (PTE), nylon (PA).

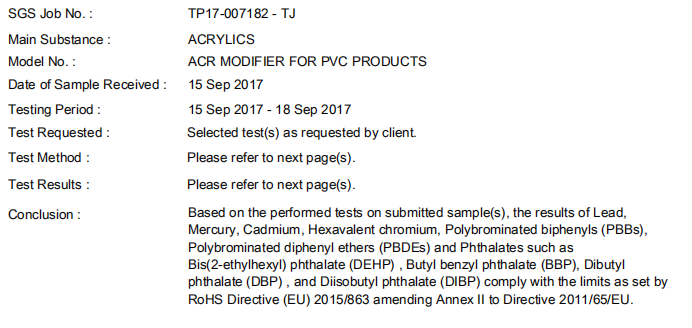

Result of SGS Test Report: